- Johnson Controls

- History

About Us

HistoryOur History

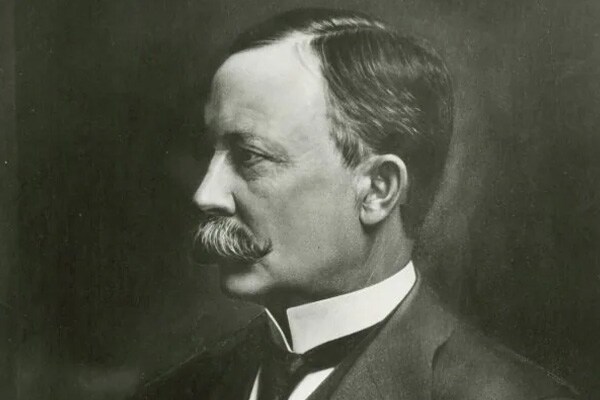

In 1885, long before anyone talks about carbon footprints or climate change, Warren Johnson launches a company to explore new ways to harness and conserve precious energy resources. In doing so, he also launches a tradition of customer-focused innovation—a tradition that has inspired thousands of employees for more than 130 years and that continues to drive the success of Johnson Controls. Even before he founds the firm now known as Johnson Controls, Warren Johnson is the quintessential inventor. His pneumatic tower clocks, electric storage batteries, wireless telegraph business and steam-powered luxury cars and postal service trucks anticipate—and shape—the future.

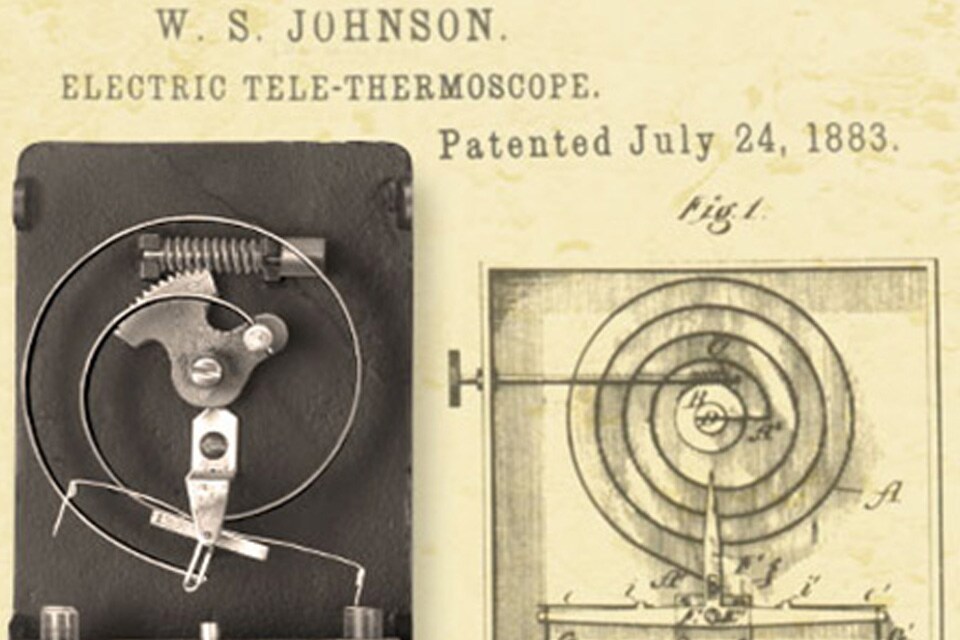

1883

Warren Johnson patents the “electric tele-thermoscope,” a building temperature-control device, and travels from his Whitewater, Wis., home to Milwaukee in search of manufacturing financing.

1885

Warren Johnson partners with Milwaukee businessman and financier William Plankinton to form the Johnson Electric Service Company. Johnson serves as vice president and treasurer, and Plankinton as president. Installations at the Milwaukee Public Library and city hall help the business grow quickly.

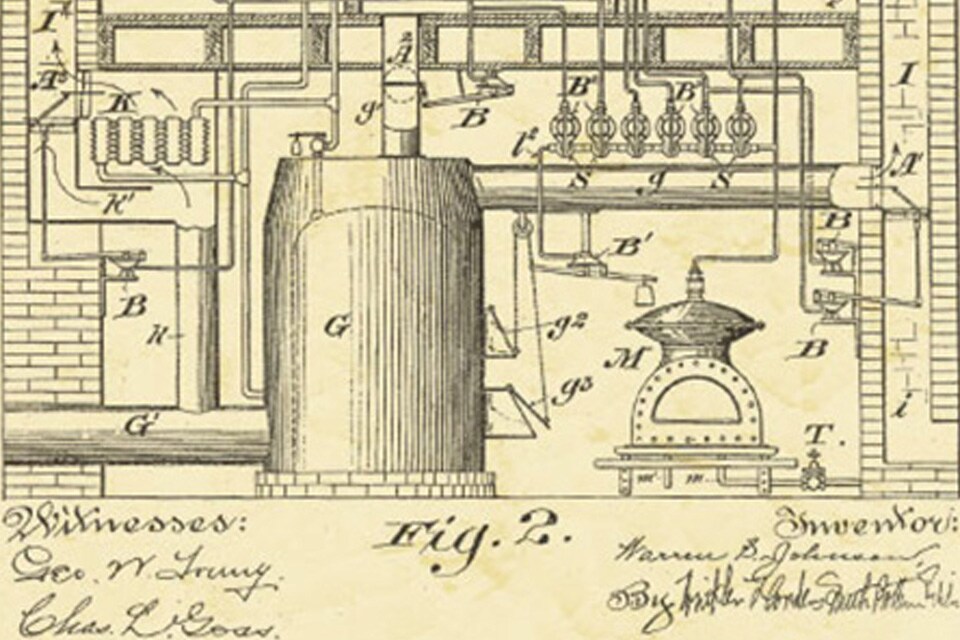

1895

Warren Johnson and associates patent steam valves, steam traps, pressure reduction valves, water heaters, hydraulic air compressors and electric meters in developing the first automatic zone temperature control system. A century later, the American Society of Mechanical Engineers calls it “the grandfather of all control systems.”

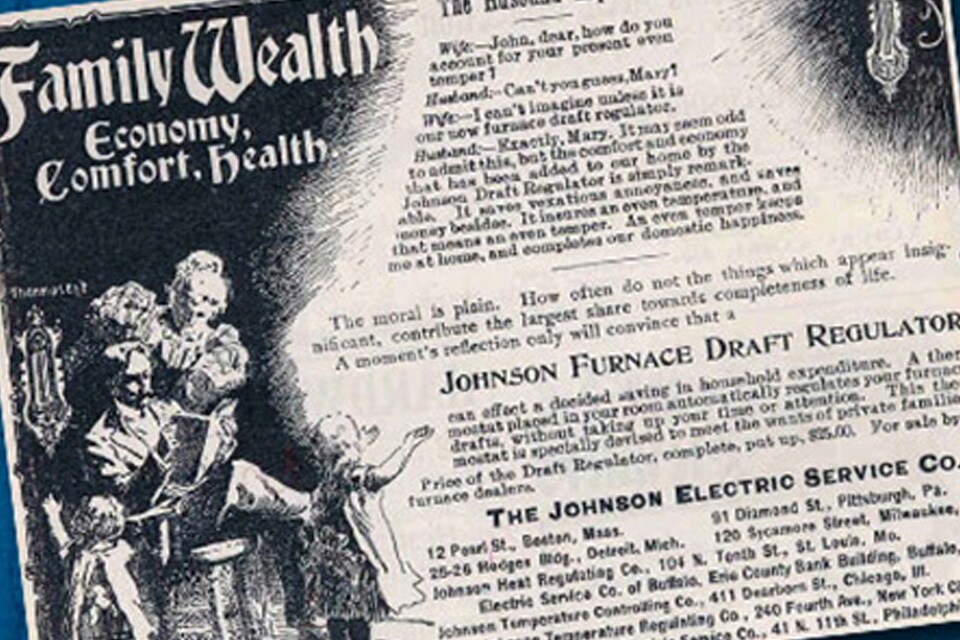

1896

A McClure’s magazine ad promises “domestic harmony and budget savings” with the Johnson Electric Service Company Furnace Draft Regulator.

1901

William Plankinton retires and Warren Johnson becomes president. Johnson’s drive for innovation leads to patents for an “auto-carriage” steam generator and a forerunner of power steering. Over the next 11 years, Johnson Electric Service Company makes 1,000 steam-powered cars, fire trucks, limousines and ambulances.

1902

With installations worldwide—including the U.S. Capitol, the New York Stock Exchange, a Warsaw factory and a palace in Tokyo—Johnson Electric Service Company changes its name to Johnson Service Company and moves to the downtown Milwaukee site that is now headquarters for Johnson Controls Building Efficiency.

1907

Johnson Service Company introduces a line of gasoline cars featuring luxurious leather and wood interiors.

1908

The first skyscraper, Singer Sewing Machine’s New York City headquarters, has “every approved modern device for comfort, convenience and safety,” including 1,200 Johnson Service Company room thermostats. Future Johnson Controls company York International’s refrigeration system delivers “a continuous supply of cold drinking water.”

1911

Globe Electric Company, a future Johnson Controls business, begins making electrical equipment for streetcars and street lights, and soon adds automotive battery production.

1912

A 15-cent U.S. postage stamp acknowledges the country’s transition to the horseless carriage, depicting a postal delivery truck made by Johnson Service Company.

1913

Future Johnson Controls business Hoover Steel Ball Company opens to serve the precision bearing and automotive industries. Years later, it expands into automotive seating.

1914

Civilian construction slows during World War I, and Johnson Service Company becomes ineligible for military procurement when the U.S. government categorizes its products as luxuries. The company continues to thrive, though, by retrofitting old buildings with temperature controls.

1920

As a new decade dawns, a war-weary public seeks out entertainment. Motion pictures are all the rage, and Johnson Service Company gets into the act with a product that helps make movie houses a haven of comfort: controls for air conditioning.

1922

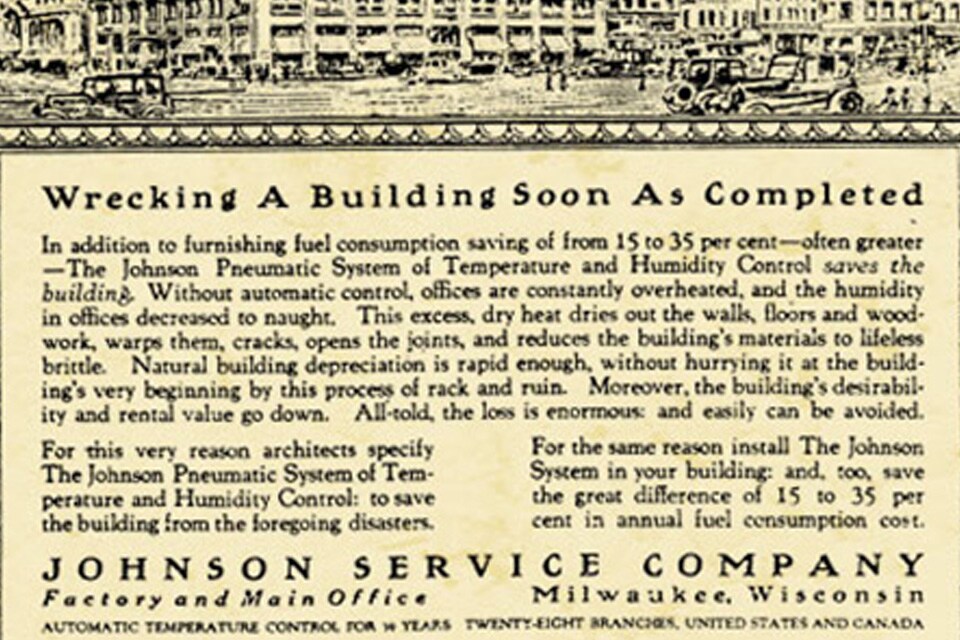

The Johnson Service Company’s pneumatic system for temperature and humidity control promises fuel savings of up to 35 percent.

1925

Johnson Service Company buys the patent for a dual thermostat developed by the chief custodian of the New York City schools (and a Johnson Service Company customer). The device lowers temperatures automatically by sensing increasing air pressure when occupants leave a room and reduces fuel consumption—a boon during the Great Depression.

1929

Many companies cut costs when the stock market crashes, but Johnson Service Company’s sales remain strong for years due to a backlog of orders—and a rising demand for the dual thermostat, which automatically cuts fuel consumption when spaces are unoccupied.

1934

A worsening economy forces Johnson Service Company to lay off workers, reduce salaries and move sales offices to salesmen’s homes. With construction stagnant, the company focuses on retrofitting older buildings with the Duo-Stat, which saves fuel by adjusting indoor temperature as outdoor conditions change.

1938

Joseph Cutler, who started with Johnson Service Company as a sales engineer in 1912, becomes president. Over the next 22 years, he reorganizes the sales force and adds 79 branch offices, and sales grow from $3 million in 1939 to $67.3 million in 1960.

1940

Johnson Service Company goes public, listing its securities over the counter.

1941

The U.S. government classifies building controls as essential to the war effort because they improve worker efficiency in defense plants and save fuel needed in combat zones. Johnson Service Company equips U.S. military training facilities and defense plants with temperature and humidity control systems.

1945

With the war’s end, new construction increases, as does demand for skilled workers. Johnson Service Company launches its first formal technical training program in New York. The Johnson Technical Institute offers the equivalent of two free years of college to employees who complete night classes or correspondence courses.

1949

The new United Nations building in New York City epitomizes a fresh generation of construction. Fully air-conditioned, it requires 3,600 Johnson Service Company thermostats and ancillary controls.

1955

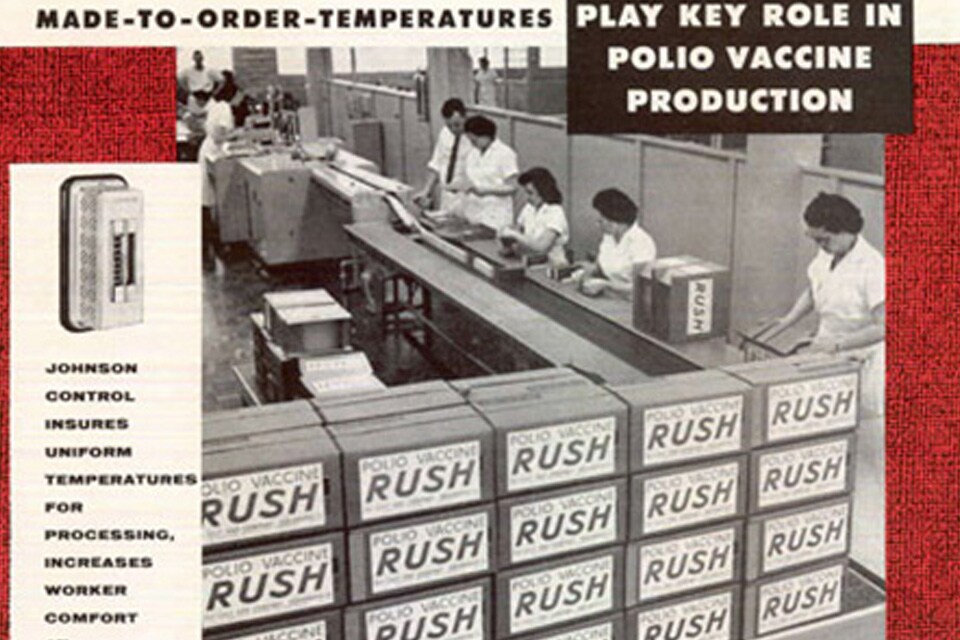

Eli Lilly & Company rushes researcher Jonas Salk’s polio vaccine into mass production at its Indianapolis, Indiana, plant. Johnson Service Company installs critical temperature-regulating apparatus in rooms where the virus is grown.

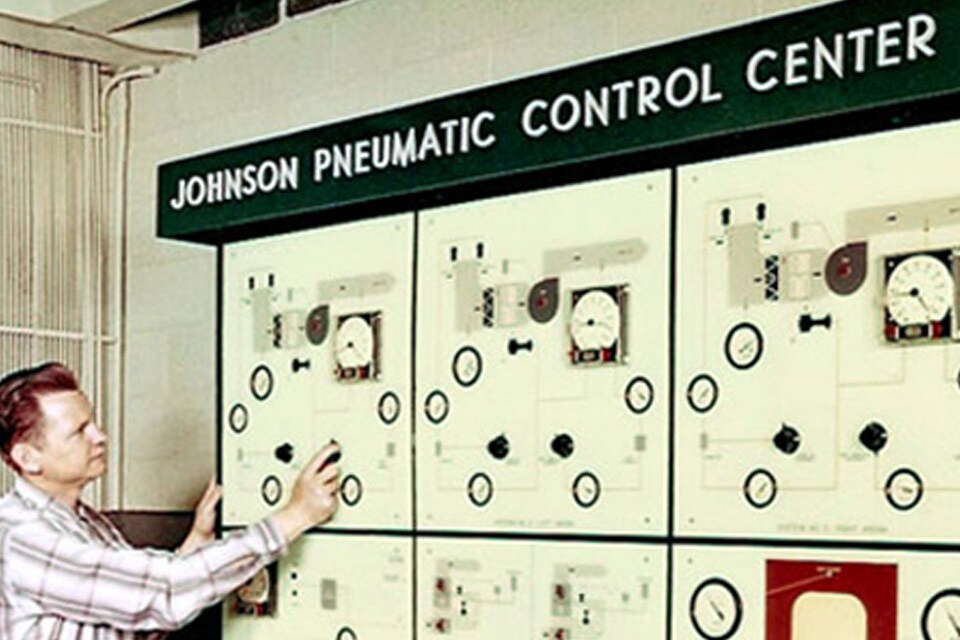

1956

Business booms for Johnson Service Company as control systems grow more complex. The numbers of employees, branches and installations hit all-time highs, thanks to demand for pneumatic control centers that let one person monitor an entire building’s room and water temperatures and ventilation from one location.

1961

Richard Murphy becomes president. He holds that position for six years, but his overall service to the company is longer than any other employee—an amazing 63 years.

1964

Having already begun serving international markets through subsidiaries in England, France, Australia, Belgium, Italy and Switzerland, Johnson Service Company builds its first European manufacturing plant in Lomagna, Italy. Worldwide sales exceed US$100 million.

1965

Now listed on the New York Stock Exchange, Johnson Service Company provides climate controls to prevent rain clouds forming in the U.S. National Aeronautics and Space Administration’s Cape Canaveral, Florida, vehicle assembly building. Future Johnson Controls company York International installs 10,500 tons of water chillers for air conditioning.

1967

Fred Brengel becomes the company’s sixth president. During his 21-year tenure, building control products are computerized, acquisitions move the company into automotive batteries and seating, and sales climb from US$140 million to $3.1 billion.

1968

Johnson Service Company enters the Fortune 500 after acquiring refrigeration and gas heating controls maker Penn Controls. Product line additions include refrigeration controls for supermarkets, humidity controls for agricultural drying equipment, and controls for commercial laundromats.

1972

Johnson Service Company introduces the JC/80, the first mini-computer for controlling building systems. It cuts fuel consumption 30 percent—and encourages building owners to automate as oil prices skyrocket. The company also adds computerized fire control and security systems for commercial buildings.

1974

The company changes its name to Johnson Controls, Inc.

1978

Johnson Controls becomes the leader in U.S. automotive battery production when it acquires Globe-Union. Founded in 1911 as Globe Electric, the company had invented the thin-wall, high-strength polypropylene battery case, a universally recognized breakthrough in battery design.

1985

Diversification at Johnson Controls continues with the acquisition of Hoover Universal (the source of its automotive seating and plastics machinery businesses), and automotive seating supplier Ferro Manufacturing. The acquisitions mean Johnson Controls can design, engineer and assemble complete automotive seating systems.

1987

The first Johnson Controls just-in-time automotive facilities in Indiana, Illinois and Ontario deliver sequenced seats to factories within hours of receiving orders. The battery unit adds Honda, Mazda and Toyota as customers and is the first aftermarket parts maker to win Ford’s “Q1 Preferred Quality Award.”

1988

Jim Keyes becomes president. During his 14-year tenure, Johnson Controls becomes a major automotive supplier, the battery division rebuilds after losing Sears as a customer, the controls division transitions from analog to digital, and overall sales increase six-fold.

1989

Johnson Controls enters facilities management by acquiring Pan Am World Services, renaming it Global Workplace Solutions, and initiates annual forums that attract speakers such as U.S. Presidents George W. Bush and Bill Clinton and Vice President Al Gore to discuss energy issues and climate change.

1990

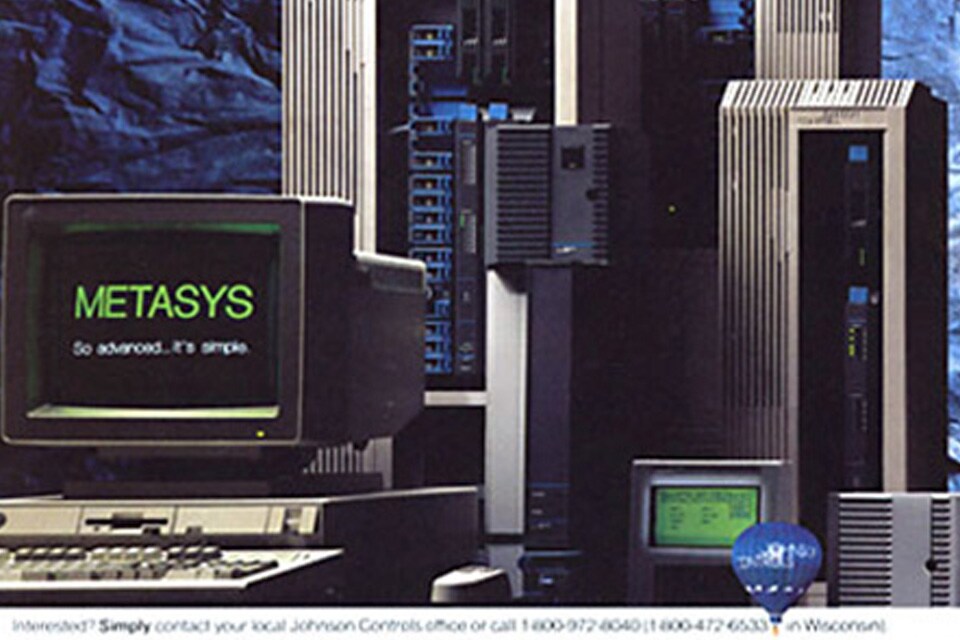

The breakthrough Metasys® Building Automation System links a building’s environmental control, energy management, lighting, fire management and security systems. Johnson Controls enters the European automotive market by purchasing an interest in German component maker E.A.H. Naue GmbH & Co. KG.

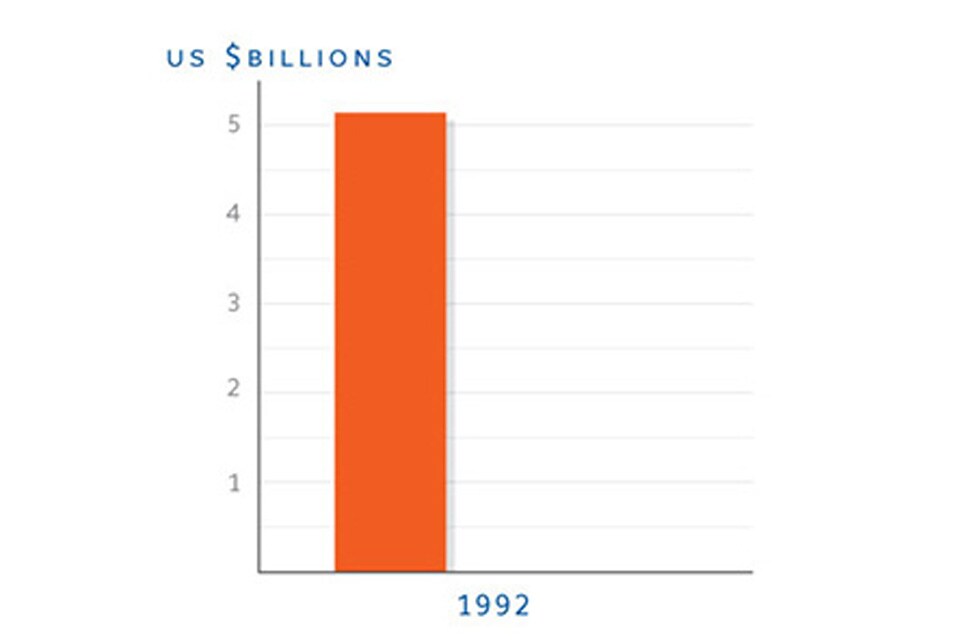

1992

Johnson Controls achieves US$5.2 billion in sales.

1994

When Sears ends its relationship with Johnson Controls, company leaders respond by implementing best business practices that identify key metrics to drive performance and reduce costs companywide. All the lost business is replaced even before Sears returns as a customer two years later.

1996

Johnson Controls makes seats for more than eight million new automobiles, is listed in Industry Week Magazine’s “100 Best Managed Companies in The World,” acquires Prince Automotive and greatly expands its automotive interior systems business. Sales approach US$10 billion.

1997

Having been in plastics since acquiring Hoover Universal, Johnson Controls is the largest U.S. soft drink bottle supplier and recycler and the world leader in plastic manufacturing and recycling technology—but sells its container and plastics machinery divisions to focus on core products. Making seats for Beijing Jeep opens new markets in China.

1998

Johnson Controls ranks first among South America’s automotive seating suppliers, installs its 10,000th Metasys® Building Automation System and acquires the Becker Group, a European automotive interior supplier, and Cardkey integrated security solutions.

1999

The U.S. Environmental Protection Agency’s Energy Star Buildings program names Johnson Controls “Ally of the Year.” The company also receives a General Motors “Supplier of the Year” award and the “Mandela International Award for Good Diversity Practices.”

2000

Johnson Controls acquires Japanese automobile seat supplier Ikeda Bussan and introduces the Auto Vision in-vehicle video system. The company’s Brengel Technology Center in Milwaukee is one of the first buildings in the world certified under Leadership in Energy and Environmental Design® (LEED).

2001

Terrorists crash a jetliner into the U.S. Pentagon on September 11, killing 64 passengers and 125 people inside in the resulting firestorm. The Pentagon facilities manager says a Johnson Controls building operations control center installed two months earlier let him close dampers to contain fire and smoke, potentially limiting further casualties.

2002

Johnson Controls acquires its Varta automotive battery division based in Germany. Sales exceed US$20 billion. John Barth is named the company's eighth CEO.

2003

The company acquires Borg Instruments of Germany and is named to the Billion Dollar Roundtable for exceeding US$1 billion in purchases from diverse suppliers.

2004

The U.S. Advanced Battery Consortium taps Johnson Controls to develop Li-Ion hybrid vehicle batteries. Dividends increase for the 30th year in a row. The company earns a World Environment Center gold medal for sustainable development, and the Brengel Technology Center is LEED® Gold certified.

2005

Johnson Controls makes its largest ever acquisition: York International heating, ventilating, air-conditioning and refrigeration products and services, with worldwide presence. The company also acquires Delphi’s global automotive battery business and is named to the Dow Jones Sustainability World Index.

2006

In a year of sales exceeding US$30 billion, Johnson Controls hosts U.S. President George W. Bush for a major energy speech at Building Efficiency headquarters in Milwaukee.

2007

The "open globe" logo debuts and Steve Roell is named the company’s ninth CEO. Johnson Controls is a founding partner in the Clinton Climate Initiative’s Energy Efficiency Building Retrofit Program. A joint venture with China’s Fengfan Ltd. to make sealed lead acid batteries creates an edge in developing countries.

2008

Best business practices and forecasting keep Johnson Controls ahead even as automakers suffer in a global economic crash. The company purchases US$1.65 billion from woman- and minority-owned suppliers and is Walmart’s “Automotive Supplier of the Year.” The American Society of Mechanical Engineers names the 1895 temperature control system a “mechanical engineering landmark.”

2009

Johnson Controls is a major player in reducing the Empire State Building’s energy use by up to 38 percent. Walmart makes Johnson Controls its sole source of automotive, marine, powersport and lawn and garden batteries. The re3 (Rethink, Renew, Respond) concept car, a five-passenger plug-in hybrid, debuts at American auto shows.

2010

In the company’s 125th year, its Glendale, Wis., headquarters is LEED® Platinum certified. Building Efficiency takes on its largest order ever for work on the Holy Mosque in Mecca, Saudi Arabia, and the Holland, Mich., battery plant is the first in the U.S. to make complete hybrid and electric vehicle Li-Ion battery cells.

2011

Corporate Responsibility magazine lists Johnson Controls No. 1 among the “100 Best Corporate Citizens” in the U.S. Worldwide revenue surpasses $40 billion. Acquiring German companies C. Rob. Hammerstein and Keiper/Recaro lets Automotive Experience offer a full menu of metal components and mechanisms.

2012

Power Solutions opens its first U.S. battery recycling center in Florence, South Carolina, featuring advanced environmental controls. The Stephen A. Roell Innovation Center opens in Milwaukee, underscoring the Johnson Controls commitment to fostering new ideas and creating new value for customers.

Our Founder

Our Leaders

Johnson Controls History in Motion

Chapter One: The Pursuit of Innovation

Experience the history of Johnson Controls through a journey into our corporate archives. In chapter one of our history series, we learn about what led our founder, Warren Johnson, to his breakthrough seminal invention of the thermostat and how it's still impacting the world today.

Chapter Two: International Expansion

In chapter two of our history series, we rediscover stories about the far-reaching corners of the globe where our products were proudly installed.

Chapter Three: The Daybook of Warren S. Johnson

In chapter three of our history series, we delve into entries from the 1905 daybook of Warren Johnson, the founder of Johnson Controls.

Chapter Four: The Evolution of Advertising

In chapter four of our series, we explore our corporate ad archives and reveal a story of growth, opportunity, and a deepening connection with the industries we serve. This journey through our history illuminates the power of innovation and our enduring commitment to remain focused on solving the challenges of our customers – and the world.

Chapter Five: Iconic Buildings

Throughout our history, we've been integrating our systems and solutions in buildings you may be familiar with. Starting all the way back in 1896 in Washington DC in the Capital building, to the Chicago skyline, Capital Record in Los Angeles and beyond, we've been leading the way on smarter, healthier buildings since our beginnings.

Ethics and Compliance

Throughout Johnson Controls history, it has been essential that we behave with unquestioned integrity consistent with our Company’s core values and our Ethics Policy.

Learn More

Leadership

Our management team and directors cultivate the company's success with their leadership expertise, skills and experience.

Learn More

Our Company

Johnson Controls is a world leader in smart buildings, creating safe, healthy and sustainable spaces.

Learn More

Inclusion at Johnson Controls

Johnson Controls is committed to creating a culture that values uniqueness, celebrates creativity and drives innovation.

Learn More

.jpg?la=en&h=320&w=720&hash=244C75B74F0F77521D56164450973BCD)