- Johnson Controls

- Building Insights

- Pioneering progress – our role in the polio vaccine

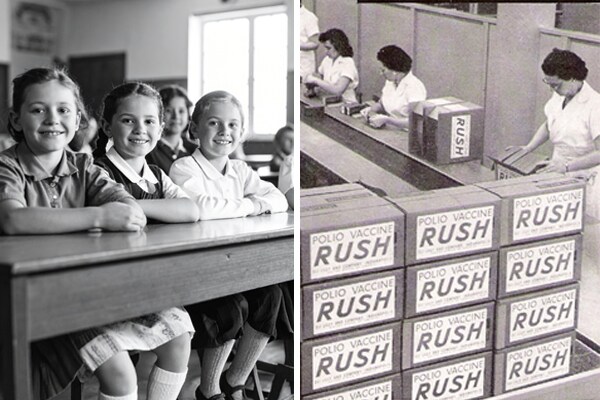

Pioneering progress – our role in the polio vaccine

During one of the 20th century’s greatest public health crises, Johnson Controls quietly played a pivotal role behind the scenes. Our technology helped enable safe vaccine production—and our commitment to environmental temperature precision still protects lives today.

Precision in critical environments

In the fight against polio, Johnson Controls played a pivotal role—helping produce one of the most important vaccines in history. Our environmental controls kept incubation rooms at a constant 96°F, a critical condition for safe, scalable vaccine production.

A crisis that gripped the world

During the mid-20th century, polio was one of the most feared diseases in the world, especially among children. The viral illness could paralyze the nervous system—and had no cure.

Between 1948 and 1955, major outbreaks caused widespread fear and changed daily life across the US, Canada and Europe. According to the World Health Organization, in 1952 alone, the US reported 57,628 cases of polio. Families avoided crowds, swimming pools and even playgrounds to reduce the risk of infection. Parents checked their children constantly for symptoms. Each summer was spent in fear of the disease.

A breakthrough—and the environment that made it possible to produce the vaccine

The development of the polio vaccine was a significant medical breakthrough. In the early 1950s, Dr. Jonas Salk and his team developed a vaccine. When it was approved in 1955, Eli Lilly & Company raced to scale up production at its Indianapolis facility.

Johnson Controls (then Johnson Service Company) had partnered with the production facility for over 40 years. Recognizing the importance of maintaining precise environmental conditions for vaccine production, Johnson Controls installed critical temperature-regulating apparatus in the incubation rooms where the virus was grown. There, Johnson Controls products kept temperatures at a constant 96°F to produce this life-saving vaccine.

According to the World Health Organization, precise temperature control was critical to the production of the polio vaccine because it ensured the virus was completely inactivated without damaging the parts needed to trigger the body’s immune response. Johnson Controls systems were instrumental in maintaining the necessary stable environment, ensuring the vaccine's efficacy and safety during production.

That precision enabled consistent output—and helped reduce polio cases in the US by up to 90% in just two years.

From life-saving science to smart infrastructure

That moment marked more than a milestone—it defined our legacy of impact. Our commitment to precision environments shaped one of history’s greatest public health achievements.

Today, that same expertise powers advanced HVAC, cleanroom and control systems for modern pharmaceutical labs and production facilities worldwide—ensuring optimal environments for breakthrough discoveries.

And it doesn’t stop at science. From vaccine labs to hyperscale data centers and high-security research facilities, mission-critical environments rely on stability, control and trust. With a long history of supporting complex operations, Johnson Controls helps create the conditions where innovation thrives and infrastructure performs at its peak.

From vaccine breakthroughs to smart infrastructure, Johnson Controls continues to deliver precision where it matters most.

.jpg?la=en&h=320&w=720&hash=244C75B74F0F77521D56164450973BCD)

.png)